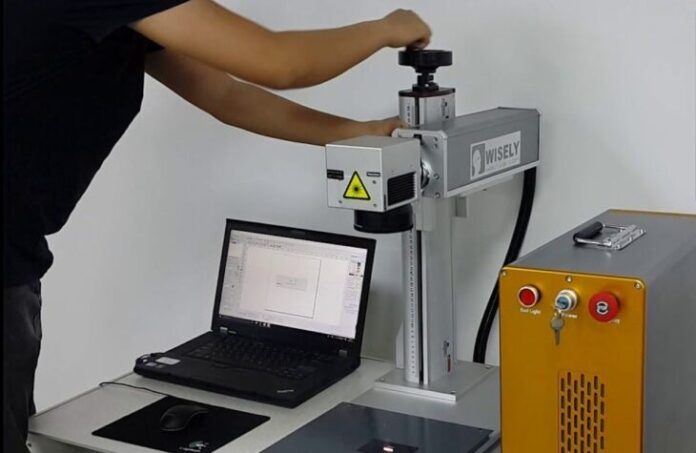

Buying a laser machine for engraved markings can be a good business idea. Technology has evolved, so people rarely depend on traditional methods of engraving. These machines use a computer; thus, they do high efficient work.

Establishing a laser engraving business can be a challenging task at first. Many machines are on the market, and it is hard to determine which will serve you well. Click here to get answers from experienced persons who are ready to offer any help regarding laser machines. There are many factors to consider before settling for the best laser machine.

Budget

If you are new in the business, purchasing a laser machine can be strenuous and, you need to dig deeper into the pocket. However, you can use finance- to- own option; choose the package that suits your needs. Most companies provide such opportunities after training the user and pay after accumulating some profits. Banks also offer loans to machine financing and grants for schools, non-profit-making organizations, and many more.

Availability of Spare Parts

It is rare for a new laser machine to develop mechanical issues. The real test comes after being in operation for a long time. Things get more complicated if it breaks down and there is work to do. So, before purchasing a laser machine, it’s vital to know if the spare parts are readily available and where to obtain them.

Materials

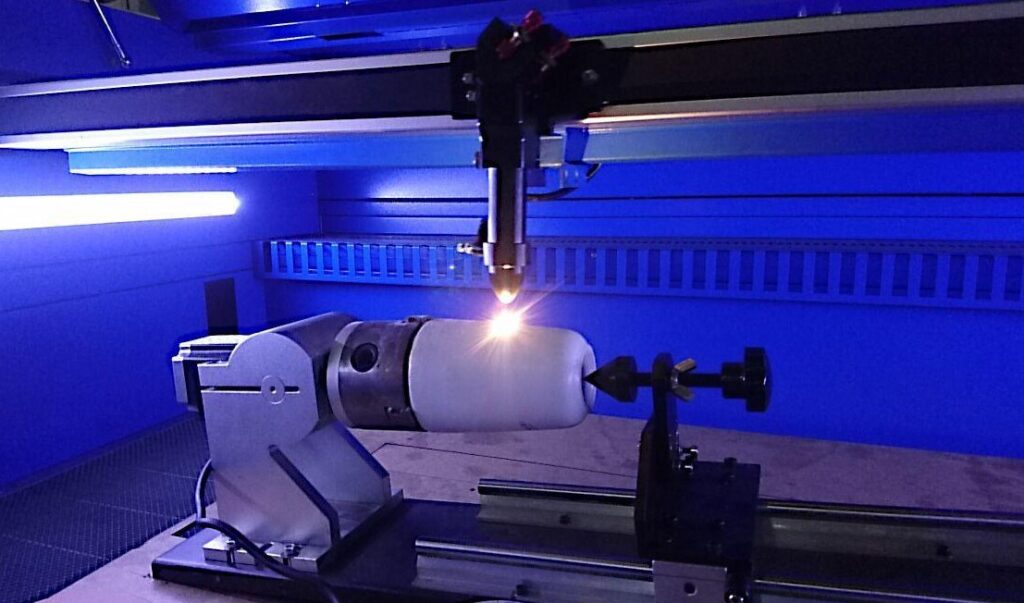

It is necessary to know the materials to use before purchasing a laser machine. The common ones are glass, plastic, rubber, cloth, ceramic, and many others. Each machine is designed to use authentic materials. You can test the device by cutting your preferred materials to know the speed used, power, results, etc.

Work Area

Determining the size of the work area is a critical aspect to consider. This depends on the lengths of the materials to work on. Also, consider the work density to ascertain the amount of space the materials will use before and after engraving.

Accuracy

Engraving machines have two transmission methods, namely, lead screw and rack gear drive. Both ways have different accuracy options, with lead screw ranking higher. Also, a device that is assembled with high proficiency has high accuracy. A square engraving machine and one with a more excellent spindle have high accuracy rates.

Maintenance

Regardless of the type of machine, maintenance is a must. So, know the type and frequency of care required. Can you handle it yourself, or you need to hire an expert? Ask around and know which machine is easy to repair and maintain to avoid huge expenses.

Power Usage

There are various factors to consider before settling for the appropriate power for a machine. The power outage in a machine will determine the kind of materials it can engrave/ cut. The speed used for cutting or engraving materials also determines the power to employ. For instance, to cut a 2-6 mm piece of wood, the appropriate power usage is 30W.

However, the commonly found AP machines use a 100w laser tube which can be used to cut/engrave various materials.

Operation Knowledge

It is essential to know how to operate a laser machine, understand its structure and simple maintenance practices. Also, learn the safety rules while handling the device. Learn how to stay safe and rescue plans to avoid accidents and injuring workers. Safety is paramount.

Production Capacity

Knowing the load capacity of a machine is very important. Firstly, evaluate your business worth and capital budget. Also, see the amount of work that a machine can handle daily. However, businesses grow, so do not purchase a low production machine.

The world has many options for engraving materials, but lasers are reliable, efficient, and affordable. They produce high-quality markings that last long. Now that we’ve known the factors to consider before buying a laser machine let’s check their advantages.

Advantages of Laser Marking Machines

Used on Variety of Materials:

The laser technology accommodates materials such as metal, ceramic, glass, and plastic. These benefits companies that use more than one manufacturing material.

Non-contact method:

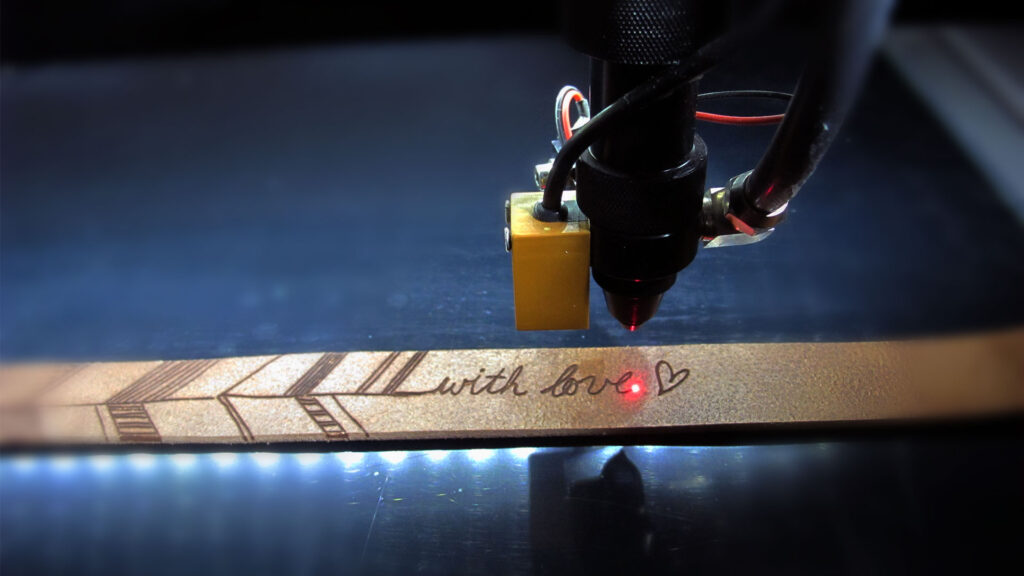

The significant benefit of laser engraving is that it doesn’t touch the material physically while working on it; the heat does the work. The traditional methods leave abrasion on the materials while the laser machine works on the targeted area without affecting the surrounding.

Faster output:

These machines use high speed to print detailed work. Operating a laser machine using a computer is very easy to get accurate prints.

Safe process:

Laser marking machines focus on the safety of workers and consumers. Traditional methods used harmful chemicals that affected the workers.

Focus on quality:

Laser machines produce high-quality engravings that are clear, permanent, and legible. The legibility is clear to human and machine scans without compromising on quality.

Used by different companies:

Laser technology is used worldly by various companies to produce high-quality marks. From engraving jewelry, ceramic tiles, and others, laser marks have benefited many businesses worldwide.

Prevents counterfeiting:

A product engraved with a laser marking cannot be replaced with counterfeits easily. The marks are original and unique, which is hard to copy.

Environmental friendly:

The laser machine uses no chemicals as opposed to its predecessors. It leaves fewer waste materials as most of it is vaporized and turned into dust particles.

Permanent markings:

Printings done by a laser machine last long since they don’t fade or peel. Whether you handle the prints roughly or expose them to the harsh climate, laser-produced markings do not peel off during transportation.

No additional treatment is needed:

Laser markings do not require a post and pretreatments like other traditional markers. It uses no chemical, thus the best printing option to use on edible product packages.